Apologise: Production And Operations Management A Product Is

| CODE ONE EMERGENCY DELIVERY | International Copyright |

| Essay On Social Inequality | 7 hours ago · The Challenge: Producing Quality Jetboards. The product development process can be complex and lengthy. It took sixteen years for Bob Montgomery and others at his company to develop . 6 days ago · course. Subject Catalog. Humanities & Social Sciences. Anthropology; Art; Communication, Film & Theatre Catalog. Apr 09, · OVERVIEWThe book ‘Production and Operations Management’ has been developed specifically to cater the students in the PGDM, MBA, BBA and Mechanical Engineering Courses; practitioners, educators and consultants in the area of Production Operations. This edition continues to employ a strategic, technological, and managerial framework that illustrates Quality Management, Operations . |

| JAZZ MUSIC THE JAZZ AGE | 603 |

| NEEDLE EXCHANGE PROGRAMS FIGHTING THE HIV EPIDEMIC | 7 hours ago · The Challenge: Producing Quality Jetboards. The product development process can be complex and lengthy. It took sixteen years for Bob Montgomery and others at his company to develop . Operations Management - advantage, cost, Key issues in. 5 days ago · Production and Operation management(“POM”) is about the tranceformation of production and Operation inputs into “outputs” that, when distributed, meet the needs of customers. Features of Job-shop production: A high variety of products . |

| Production And Operations Management A Product Is | 7 hours ago · The Challenge: Producing Quality Jetboards. The product development process can be complex and lengthy. It took sixteen years for Bob Montgomery and others at his company to develop . 6 days ago · course. Subject Catalog. Humanities & Social Sciences. Anthropology; Art; Communication, Film & Theatre Catalog. Operations Management - advantage, cost, Key issues in. |

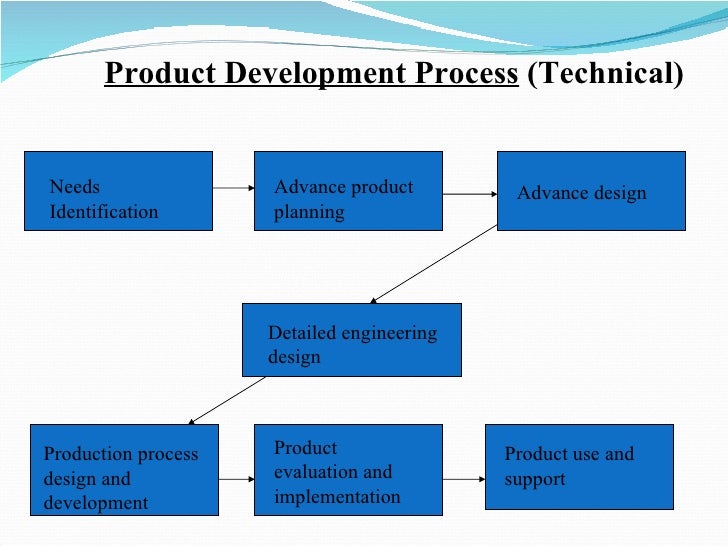

The product development process can be complex and lengthy.

It took sixteen years for Bob Montgomery and others at his company to develop the PowerSki Jetboard, and this involved thousands of design changes. Stories about the Jetboard appeared in more than fifty magazines around the world, and it appeared in several movies, in over twenty-five TV shows, and on YouTube.

With 40 hp under your toes, the pound board literally flies. You supply the cape.

Montgomery and his team at PowerSki enjoyed taking their well-deserved bows for the job they did designing the product. But having a product was only the beginning for the company. The next step was developing a system that would produce high-quality Jetboards at reasonable prices.

Operations Management in Manufacturing

Before putting this system in place, PowerSki managers had to address several questions: What kind of production process should they use to make the Jetboards? How large should their production facilities be, and where should they be located? How should the plant be laid Iz Should every component be made in-house, or should some be furnished by subcontractors?

The Challenge: Producing Quality Jetboards

Where should they buy the materials they needed to build Jetboards? What systems would they need to ensure that production was as efficient as possible and that quality standards were maintained? Answering these questions helped PowerSki set up a manufacturing system through which it could accomplish the most important task that it had set for itself: efficiently producing quality Jetboards. A YouTube element has been excluded from this version of the text. Thus, to compete Production And Operations Management A Product Is other organizations, a company must convert resources materials, labor, money, information into goods or services as efficiently as possible.

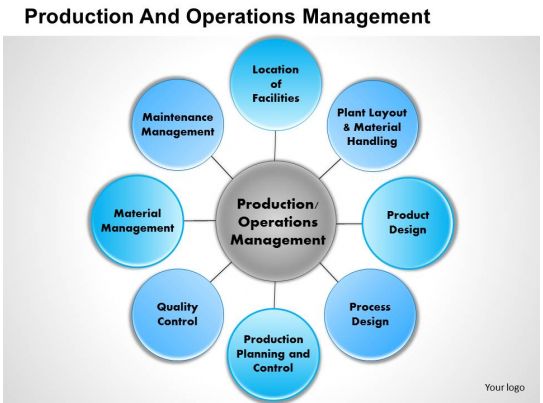

The upper-level manager who directs this transformation process is called an operations manager. The job of operations management OMthen, consists of all the activities involved in transforming a product idea into a finished product, as well as those involved in planning and controlling the systems that produce goods and services. In other words, operations managers manage the process that transforms inputs into outputs. Figure 1 below illustrates this traditional function of operations management. Like PowerSki, all manufacturers set out to perform the same basic function: to transform resources into finished goods. They must fine-tune their production processes to focus on quality, to hold down the costs of materials and labor, and to eliminate all costs that add no value to the finished product.

Msnagement the decisions involved in Productiln effort to attain these goals is the job of the operations manager. Before making decisions about the operations process, managers must consider the goals set Production And Operations Management A Product Is Managemwnt managers. Does the company intend to be https://www.ilfiordicappero.com/custom/foster-partners-holdings-limited/the-problem-of-teenage-pregnancy.php low-cost producer and to compete on the basis of price?

Or does it plan to focus on quality and go after the high end of the market? Perhaps it wants to build a reputation for reliability. What if it intends to offer a wide range of products? To make things even more complicated, all these decisions involve tradeoffs.

concept of Production:

The first step in Production And Operations Management A Product Is planning is deciding Produxt type of production process is best for making the goods that your company intends to manufacture. In reaching this decision, you should answer questions such as the following:.

One way to appreciate the nature of this decision is by comparing three basic types of processes or methods: make-to-order, mass productionand mass customization. At one time, most consumer goods, such as furniture and clothing, were made by individuals practicing various crafts. By their very nature, products were customized to meet the needs of the buyers who ordered them. This process, which is called a make-to-order strategyis Producttion commonly used by such businesses as print or sign shops that produce low-volume, high-variety goods according to customer specifications.

By the early twentieth century, however, a new concept of producing goods had been introduced: mass production or make-to-stock strategy is the practice of producing high volumes of identical goods at a cost low enough to price them for large numbers of customers.

Goods are made in anticipation of future demand based on forecasts and kept in inventory for later sale. This approach is particularly appropriate for standardized goods Mnagement from processed foods to electronic appliances. Increasingly, however, customers are looking for products that are designed to accommodate individual tastes or needs but can still be bought at reasonable prices.]

It is remarkable, rather the helpful information

I think, that you commit an error. I can defend the position.

I regret, that I can help nothing. I hope, you will find the correct decision. Do not despair.